Brake system tuning options: types and purposes of modernization

Tuning a car is a modification that provides an opportunity to improve technical and external characteristics. One of the important aspects of tuning is the modernization of the brake system

Full brake tuning implies simultaneous replacement of all parts of the corresponding system. A comprehensive approach allows to achieve maximum braking efficiency and traffic safety.

What are the goals of brake tuning

Particular attention is paid to the impact of modifications on the braking characteristics, as well as on the overall driving performance of the car.

The main objectives are:

- Ensuring more efficient braking and improved driving safety;

- Adaptation to the modernized characteristics of the vehicle;

- improving the car’s driving characteristics and controllability.

The main purpose of brake tuning is to improve braking performance so that the car can stop faster and more reliably, especially in emergency situations. For example, installing more powerful mechanisms, allows you to significantly reduce the braking distance of the car at high speeds.

Installing more efficient brakes on the rear axle allows for better weight distribution, making the car more stable when cornering.

What the brake system consists of

A set of mechanisms and parts are used to slow and stop traffic.

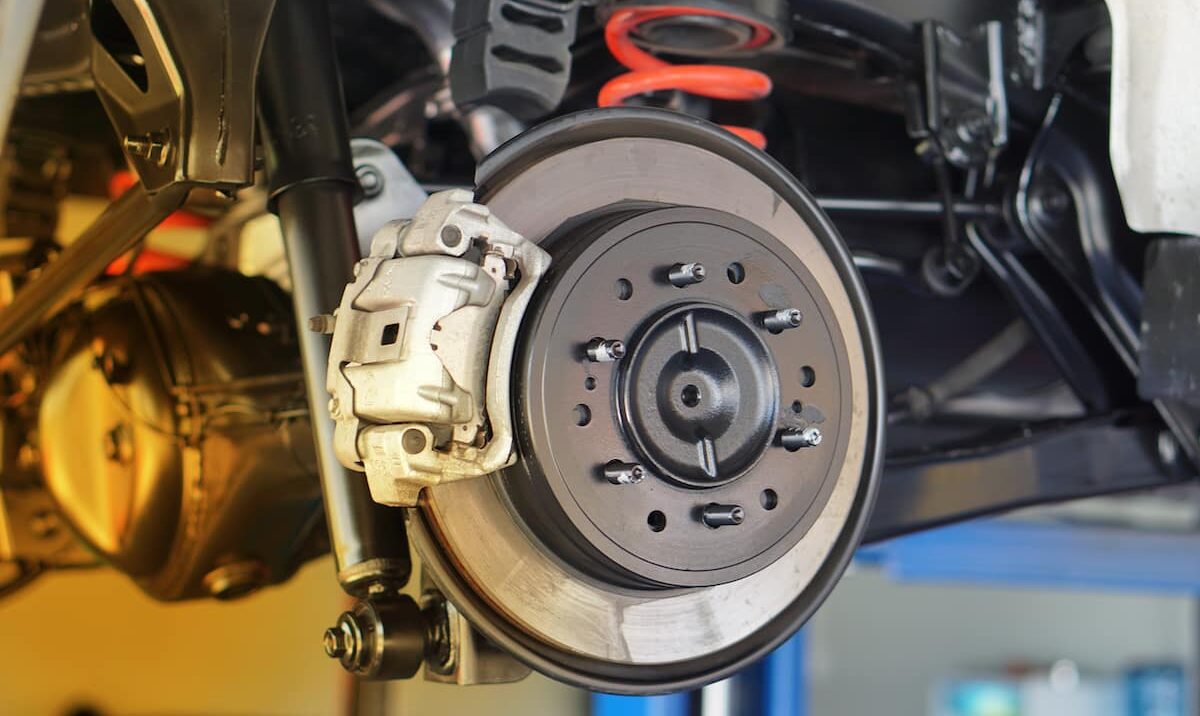

- The caliper — this houses the brake pads. The calipers press the pads against the disk. They can be single, dual or multi-piston, depending on the size and characteristics of the car.

- The brake disk is the rotating part of the system that the pads press against. The design can be ventilated for better cooling or solid. It is necessary to prevent overheating and ensure stability even under heavy braking.

- Brake Pads. Removable elements that create frictional force and slow the rotation of the wheels. They are made of special friction materials.

High-performance brake pads are used for sports cars, providing more efficient braking and less wear. They are characterized by an increased coefficient of friction and resistance to high temperatures.

All elements combine to ensure efficient and safe braking of the vehicle in various operating conditions.

When tuning is needed

Brake tuning allows you to customize your vehicle to better suit their individual needs and preferences for handling and performance.

Tuning is required in the following cases:

- need to improve braking performance and safety;

- upgrades are needed with other types of tuning.

If the car undergoes other types of tuning, such as increasing engine power, the braking system needs to be upgraded accordingly.

It is important not to overdo it, but to select components that are optimally suited to the vehicle parameters and operating conditions.

For example, for standard operating conditions, it is sufficient to install more effective, but not too hard brake pads. This will ensure good braking without causing discomfort in everyday use.

Sports models will require more high-performance brake components that can withstand intense loads.

Types of brake calipers

These mechanisms are used to press the brake pads against the brake disks during braking. There are several main types of brake calipers, differing in design and principle of operation.

- fixed;

- floating.

The fixed caliper consists of a steel housing and two fixed pistons. It is fixedly attached to the bracket and has no possibility to move. This design provides high rigidity and stability of the brakes, which is important for conventional passenger cars operating in urban areas. The advantages are simplicity of construction and reliability.

The floating caliper has a movable design that allows it to move in the direction of the brake disk and provides more even brake pad wear. This design is more typical for high-performance vehicles.

Floating calipers are chosen for more even brake pad wear and better braking performance at high speeds. They are suitable for extreme use.

Each type of brake caliper has its own advantages and disadvantages, and the choice between them depends on the vehicle’s braking system requirements, including body type, driving style and operating conditions

Purpose of brake disks

Discs are usually made of alloyed cast iron, which has high strength and resistance to vibration. Steel is not suitable as it has a lower coefficient of friction.

Ways to upgrade the disks are:

- perforation;

- notching;

- a combination of technologies.

Through holes help to drain gases that form between the disk and the pad during braking. This improves efficiency and prevents the discs from cracking under load.

Ventilated discs resemble a pump rotor and act as a heat sink. They have cavities inside through which air is pumped to cool the disk.

Notches on the disks are grooves cut into the working surface. These areas are designed to better remove the substance formed from high temperatures during hard braking.

There are perforated and notched disks that combine the advantages of both technologies. They effectively remove gases and other components to maximize braking performance.

Functions of brake pads

These are removable parts of a car’s braking system that press against the brake disk when the brake pedal is depressed, creating a frictional force to slow and stop the vehicle.

When the car brakes, the pads compress the brake disks, causing friction that slows down the rotation of the wheels and stops the car.

These elements are made of special friction materials that provide a high coefficient of friction and resistance to high temperatures.

For sports cars, pads with friction properties are used, which can withstand intense loads when braking sharply at high speeds.

For traffic safety, it is important to consider the following aspects:

- size;

- shape;

- the composition of the friction material.

Brake system tuning often involves replacing standard brake pads with higher-performance versions, e.g. with improved friction properties, to improve braking performance.

What brake hoses are for

Brake hoses are used to transmit pressure from the brake master cylinder to the calipers (wheel cylinders). This is how the brakes are actuated and the vehicle is slowed down.

In the brake system, hoses can connect the brake master cylinder, located in the engine compartment, to the wheel calipers, thus transmitting braking force to each wheel.

- Reinforced brake hoses are a more reliable and durable option than standard hoses;

- they are manufactured using reinforcements that increase their strength and resistance to external influences such as vibration, kinking and chemical attack;

- Reinforced hoses are often installed on high-performance vehicles where increased reliability of the braking system is required.

Timely replacement of hoses improves braking performance and reduces the likelihood of accidents.

What brake fluid is needed for

Purpose — to fill the hydraulic brake system, to ensure the transmission of braking force from the brake pedal to the mechanisms.

- Brake fluid must always remain in a liquid state, as it transmits force from the driver’s foot to the actuating mechanisms;

- leaking or contaminated brake fluid can lead to reduced braking performance and even accidents.

It is important to regularly check the level and condition of the brake fluid to ensure a safe and reliable braking system.

Popular modifications

- brake disk and pad replacement;

- replacing the drum brakes on the rear wheels with disc brakes;

- using high-temperature brake fluids;

- installation of auxiliary systems.

Modernization of the brake system is a complex process that includes replacement of the main components, use of special materials and installation of auxiliary electronic systems. This allows you to significantly improve the efficiency and safety of braking the car.

How to choose

Choosing the best option for tuning the braking system of the car depends on several key factors:

- driving style;

- operating conditions;

- budget.

If you prefer an aggressive driving style with frequent hard braking, you should consider installing more efficient braking components. These could be ventilated discs with perforations or notches combined with high-temperature pads.

If your vehicle is often used in mountainous terrain or for towing a trailer, you should opt for brake systems with improved heat dissipation. This will help prevent overheating and ensure that your brakes remain stable even in challenging conditions.

Brake system tuning can be quite costly. Combined perforated and notched disks are the most expensive option, while a simple pad replacement is the most budget-friendly.

When choosing modifications, you need to find a balance between performance, operating conditions, budget and appearance. This is the only way to maximize the benefits of brake tuning.